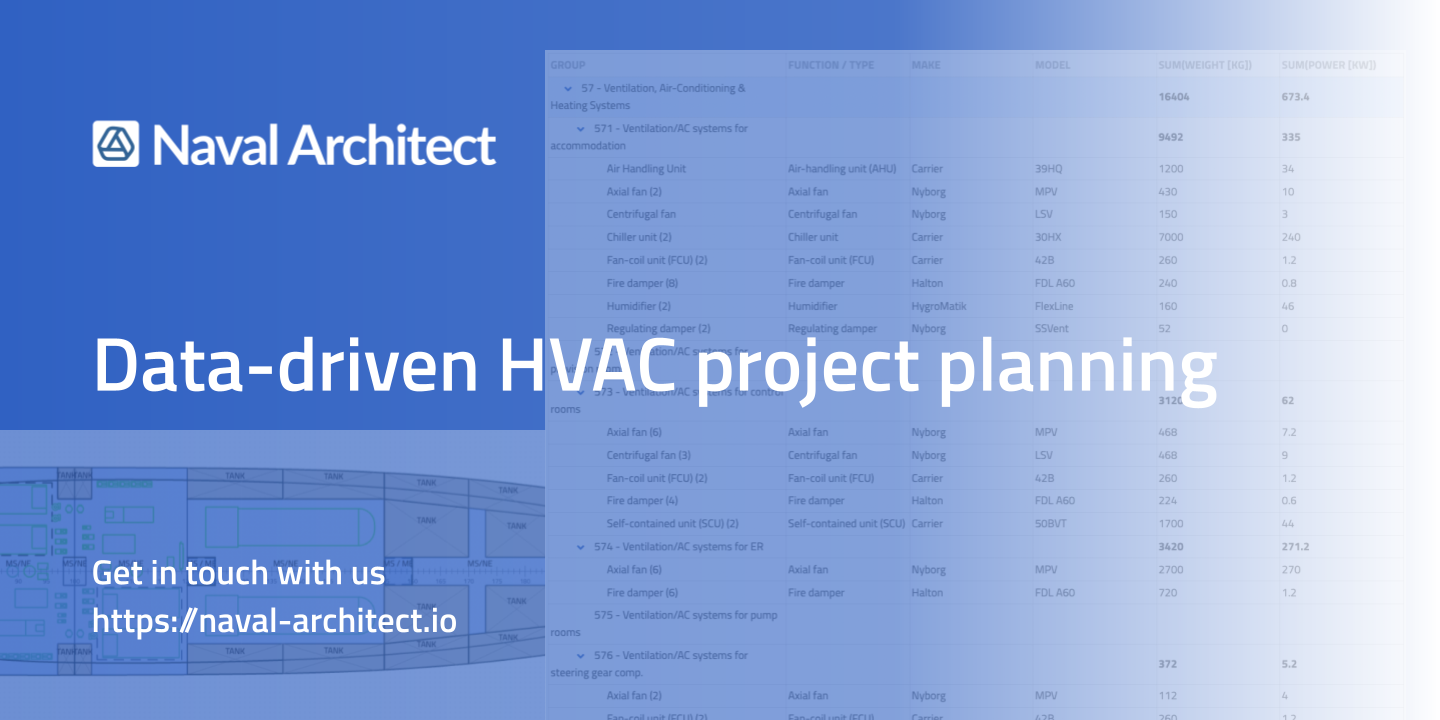

Heating, Ventilation, and Air Conditioning (HVAC) are one of the most complex and widespread, yet…

Why Ship Information Modeling (SIM) will become the future industry standard

Naval Architect’s vision is a comprehensive digitalization of the shipbuilding industry – from ship design over manufacturing to subsequent ship operation – based on a shared digital ship model. We call this vision “Ship Information Modeling (SIM)”.

Ship Information Modeling (SIM)

SIM describes a working method for the connected planning, design, construction and management of ships with the aid of software. All relevant ship data is digitally modeled, combined and recorded. The structure is also visualized geometrically as a virtual ship model. It is continuously maintained throughout the ship’s life and is the essential source of information when it comes to data about the ship. Relevant information such as the ship’s physical and functional characteristics and attributes (including type of the component, materials, physical properties, equipment, time and cost data) are all interlinked with the digital ship model.

Benefits of SIM

Ship Information Modeling promotes efficient collaboration and minimises risks in shipbuilding projects with better information management. Specifically, it offers the following benefits:

- Maximum efficiency and productivity: Collaboration between the different project participants on the basis of a central database without manual data exchange. This increases the working efficiency and productivity. Saving many redundant steps with better project coordination and transparent presentation of project progress by merging project data in a central database. Easy collaboration in globally distributed networks on the basis of a cloud-based platform.

- Consistency and transparency for reduced risk: Always up-to-date information, such as technical drawings and specifications. This minimises the risk for costly planning and design errors from project start. Reliable determination of quantities, areas, volumes and other relevant parameters for all stakeholders set the basis for reliable cost and time planning. Different designs and concepts can be modelled, tested and aligned in the virtual ship model. Any inconsistencies and errors can be identified and fixed early on.

- Product Lifecycle Management: The information in SIM is not only useful and beneficial for planning and design phases, but also for ongoing operations, maintenance and ship management.

Read more about SIM here:

- WHAT IS SHIP INFORMATION MODEL (SIM)?

- 5 WAYS SHIP INFORMATION MODELING (SIM) IS REVOLUTIONIZING SHIPBUILDING PROJECTS

Implications going forward

The construction industry has recognizes the added value of a connected planning process based on a digital model. It is referred to by the term “Building Information Modeling” (BIM). The BIM market is already taking off and becoming the standard in many construction projects. Similar to the building and construction industry, we believe the following implications for the shipbuilding industry will become valid:

- SIM will become the standard for the shipbuilding industry

- Shipbuilding companies that use SIM will have significant competitive advantages in the future

- Shipbuilding companies that do not leverage SIM will lose a competitive edge (coordination with them is time-consuming and more costly)

- New business models will arise in the environment of SIM

Naval Architect offers a cloud-based system to specifically address the needs of Ship Information Modeling. It bundles the diverse information in ship design and presents it transparently and consistently for all project participants at all times. It complements and improves existing processes by combining and linking heterogeneous information. Naval Architect thus makes a central contribution to the successful implementation of SIM in the shipbuilding industry.

See more information about our product here: benefits | features | use-cases

If you are interested to use the ship design platform Naval Architect in your organization, you can request a free discovery call here. In this online call, we will learn about your specific requirements and give you a detailed demo of our shipbuilding software.