Weight is the most critical characteristic of any newly built ship, as we mentioned previously…

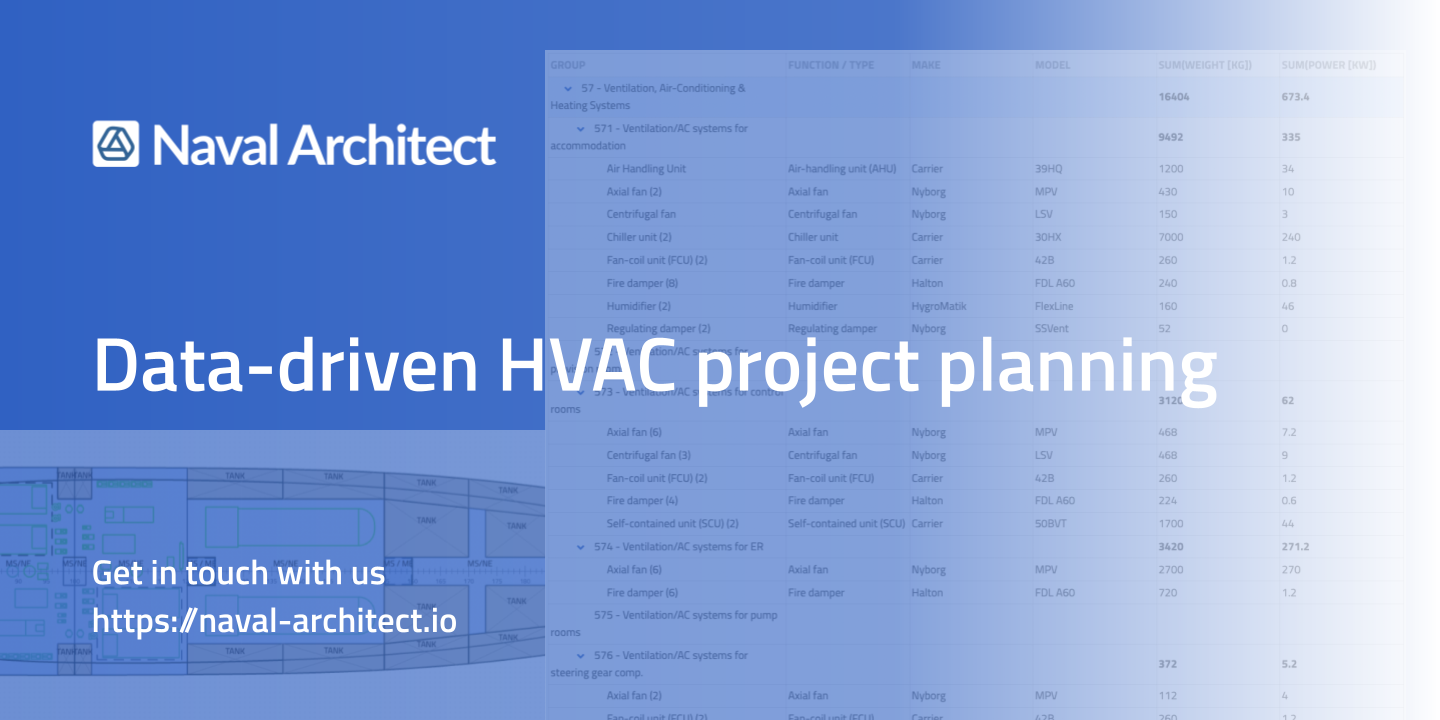

Data-driven HVAC project planning

Heating, Ventilation, and Air Conditioning (HVAC) are one of the most complex and widespread, yet often misunderstood systems on ships. Data-driven HVAC project planning in Naval Architecture helps regain control over the scope and avoid reinventing the wheel across the different stages of the project.”

The harsch environment of HVAC projects

As an HVAC contractor, you fully experience the challenges of ship production along with your clients – shipyards and design offices. You become deeply involved in common issues like limited space, weight problems, or restricted power in different operating modes of the vessel. Often, you face even more challenging situations because:

- Input data arrives to you with a delay and frequent updates.

- The input is incomplete, and you miss the overall picture.

- You have no leverage to push for conceptual changes in ship architecture that are necessary for the HVAC systems.

- You struggle to effectively communicate with the design team.

Therefore, it is extremely important to make the most of the data you receive and manage it effectively from the very beginning. Working with the General Arrangement drawing in form of a pdf or an AutoCAD drawing requires a lot of effort to manually calculate the room areas and volumes to determine required capacity of the HVAC systems.

Naval Architect allows you to configure a data model based on a simple 3D geometry right from the start of the project. Creating the data model requires similar effort compared to reverse-engineering the data provided by the shipyard. Moreover, updates are made easy because the entire data model, including all volumes and areas used in calculations, are directly tied to the easily updatable geometry.

From the draft offer to HVAC system engineering

Most requests for quotation (RFQs), that require your resources to process and create an offer, do not result in a contract. However, some of them do. In these situations, the preliminary offer faces immediate verification against a number of additional, updated, or even completely changed information from the ship designer. This is when most misunderstandings arise, such as:

- Expected versus included scope of the HVAC contractor.

- Additional requirements from Flag/Class/Operator not emphasized in the RFQ process.

- Level of automation expected in the system.

- Tight planning of ship engineering and production.

The offer created by the sales team must be easily understood and picked up by your engineering team to effectively continue the project.

Naval Architect allows for the gradual development of the project’s data model throughout the process. All information recorded in the initial design can be easily understood and utilized in subsequent stages.

Data-driven process

First versions of the HVAC offers are often based on experience from previous projects rather than the actual data provided by the shipyard. This is due to limited time and resources available for the draft offers. However, as the cooperation progresses, the accuracy of the offer becomes more critical. At some point, significant engineering effort is required to make it realistic, emphasizing the importance of a data-driven approach to:

- Incorporate data from the initial drafts and avoid reinventing the wheel at later stages.

- Consider all previously agreed-upon factors.

- Obtain the actual numbers through engineering, which translate into the final price of the offer.

This is why working in the same platform from the draft offer stage, through detailed quotations, and up to and through the engineering process is beneficial. Nothing gets forgotten, and every issue is resolved once and for all.

Test the alternatives

There is never a single solution to a problem. Even when your offer (and related engineering solutions) is quite advanced in the sales stage, there may always be a better alternative, especially when significant changes are received from the shipyard.

With Naval Architect, you can easily branch off the main project stream and modify the data. This allows you to gain insights into how potential changes in the engineering concepts affect important factors such as:

- Overall price of equipment, engineering, installation, and commissioning.

- Power consumption of the system.

- Total weight of the system.

- Impact on other ship systems.

This enables clear communication of the consequences of internal and external engineering decisions to different features of the HVAC system.

Try the data-driven HVAC project planning on your own!

Naval Architect is the industry’s first platform to boost project data management based on a digital ship model. If you are interested to learn more, let’s meet for a 30 mins session to discuss how Naval Architect can help to make your processes more efficient and reliable: Request a free demo here. We also offer a 14-day Free Trial of our platform.