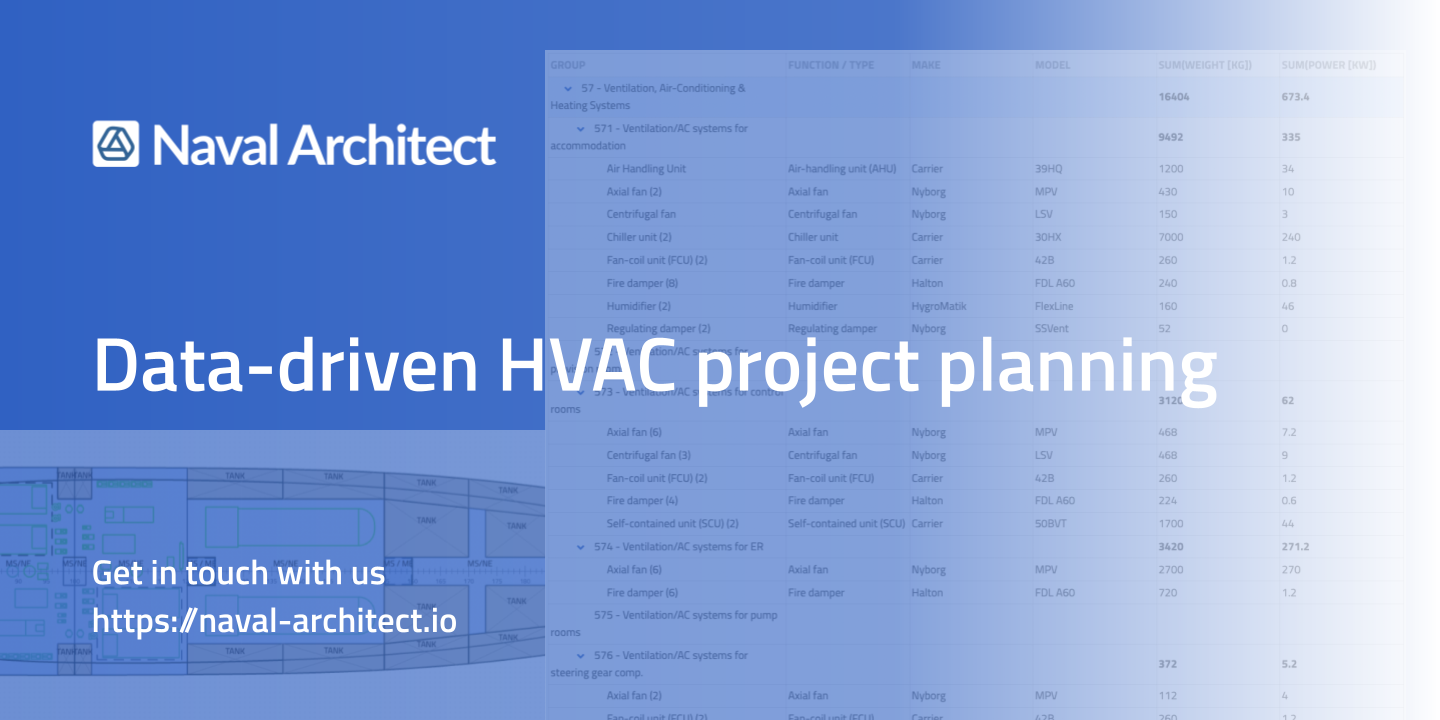

Heating, Ventilation, and Air Conditioning (HVAC) are one of the most complex and widespread, yet…

Top 3 reasons why you need an effective Engineering Change Management

Engineering Change Management

One of the most challenging aspects in shipbuilding projects is keeping track of all changes. This is especially true for the early design & engineering phase as 80-90% of the ship’s costs are already defined at this stage. Managing the change process and communicating changes across multiple departments within the company or even with external stakeholders (e.g., suppliers, design offices, subcontractors) is an increasingly complex challenge with implications that should not be underestimated: Ineffective or badly managed change processes can lead to companies facing difficulties in meeting project deadlines and managing costs.

So what is the solution to effectively manage change processes in shipbuilding projects? Engineering Change Management (ECM) is the answer for a streamlined change process to achieve a competitive advantage.

Here are the top 3 reasons why your company needs an effective ECM solution for shipbuilding:

1. Minimized manufacturing costs and errors

With a central location for all information on the ship’s data and design, the project team will work with the latest data and always know the current project status. There is no more confusion about where to find the newest design data and whether the data is still up to date.

Changes will also follow a structured process to enhance transparency and provide a clear history of change and merge requests as well as approvals. Countless emails and calls are no longer necessary.

2. Faster time to market

The time from early design to production can time-consuming due to the high coordination effort required to align changes and requirements. With an ECM there is reduced manual work required. All changes are immediately visible, and all team members have access to the latest version, minimizing the potential for errors and thus also reducing time-consuming rework.

3. Better collaboration

Engineers in shipbuilding projects spent about 20% of their time on coordination for data validation and alignments on change requests. With an effective ECM solution, this time-consuming work can be drastically reduced or even become completely unnecessary, so that users can focus on what is really important: designing and building a great ship.

An ECM solution is also useful when cooperating with external stakeholders, e.g., when shipyards align with suppliers. Any changes taking place from the shipyards side will automatically be visible for the suppliers. Shipyards always have the overview for which components an offer was already requested etc.

Conclusion

A good and robust change management solution is the key driver to reduce error costs in shipbuilding projects. The sooner an ECM solution is used, the lower the risk for unnecessary rework and additional costs later. Thus, by minimizing risks, accelerating the time to market, and achieving lower costs will give shipyards a significant ROI from ECM implementation and increasing its competitive advantage on the market.

Learn how Naval Architect can help you reduce manual errors through effective version control and product data management. Sign up to get early access to our software or schedule a live demo with us.