Heating, Ventilation, and Air Conditioning (HVAC) are one of the most complex and widespread, yet…

How Naval Architect improves the efficiency of the ship design workflow

Naval Architect is a web-based cloud platform designed to collaborate via a shared digital topological ship model. The model stores additional, customisable information and provides a toolset for efficient change management. With all this, Naval Architect improves the efficiency of the ship design workflow compared to common CAD systems out there.

Problems of common CAD systems

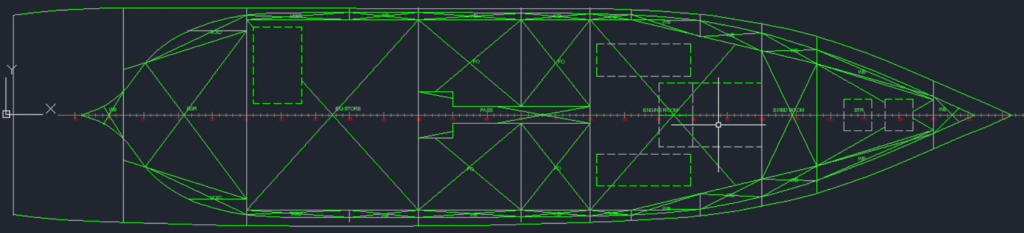

Is AutoCAD a good tool for ship design? Of course it is! After all, we all know it very well. But there’s a commonly reported problem with the popular CAD systems applied in shipbuilding. We use them for basically everything! Not just to create engineering drawings, which is their real purpose. We also try to calculate geometric properties and store project information by adding tables and annotations. And then we struggle to update it all.. manually!

And all that makes our workflow vastly ineffective!

But there are other ways to store project information! For example, many ship design companies maintain complicated PLM systems. But these aren’t easily customisable, and engineers have very limited ability to adapt them to their needs. Customisation is absolutely necessary, especially in the early stages of the complex ship design process! There’s another big player that fills this gap and is loved by many: MS Excel. It’s often used as a ‘database’, usually with poor or even disastrous results. This is because data is just not secure there: there is no version control and large datasets cannot be handled effectively. Not to mention the duplication of information both in PLM and locally in messy Excel ‘databases’.

How are our ‘databases’ in Excel doing?

A case study

Imagine the usual situation where an engineer wants to draw a deck plan and list all compartments with their floor areas and volumes. It can serve as the basis for cost estimating, HVAC system design, fire protection system design, input data for a contractor, and more. At this stage, there’s really no other option than to take the CAD drawing to manually estimate and write down this information.

How the 5D model solves the problem

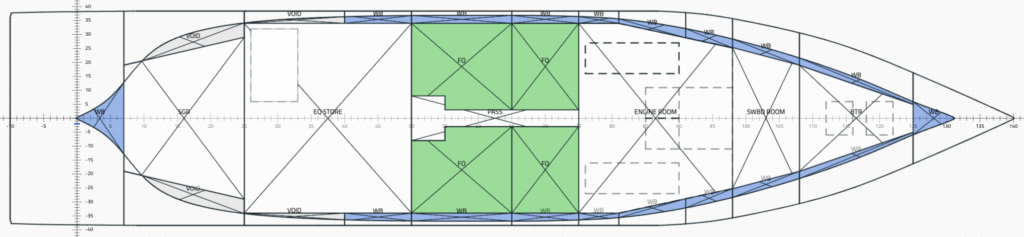

Naval Architect addresses the problem of data management with its 5D model. It’s a revolutionary combination of geometry (3D), database (+1D) and version management (+1D). Each object in the geometry ‘carries’ information. Basically, there are two main types of data:

- automatically generated geometric data, such as volumes or areas of objects – we focus here on these,

- fully customisable ‘types’ that can store any user-defined properties – more on this in the next articles.

Drafting is fairly similar to what you’re used to from other CAD systems. It’s just been customised specifically for ship design. Check out our latest video where we have show how Naval Architect improves efficiency of drawing the geometry.

Once the geometry is in place and the inner ship spaces are determined, you can take full advantage of the 4th dimension – the database. But what actually happens? With 2 mouse clicks you generate a report listing the selected information. No manual approximation and writing down the data required. The report can be downloaded in Excel format. Simple as that.

You can take full advantage of the 4th dimension – the database

And what if the geometry is updated? The changes are immediately visible in the report and clearly marked. Can you even remember times when you measured out the updated CAD drawing, jumped into the Excel spreadsheet and replaced the data by hand?

What are the numbers?

How much time does it save compared to the old fashioned CAD + Excel workflow. Well, that depends on how many changes are made during project development. We all know it’ll be a lot! After all, we’re not designing tea pots here!

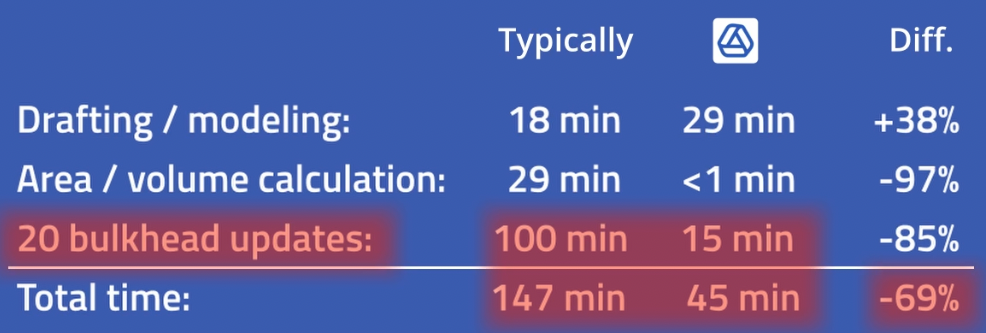

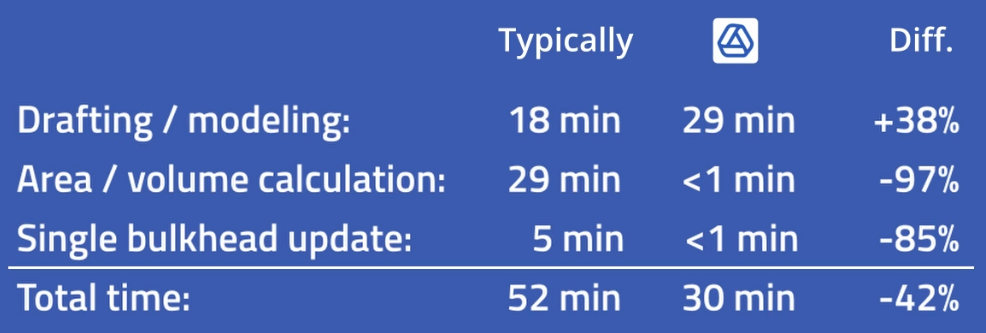

Here’s a comparison based on our check in our last video. Assuming you got your design of the deck plan 99% correct from start to finish, with only one change, you’re already saving about 42% of your time.

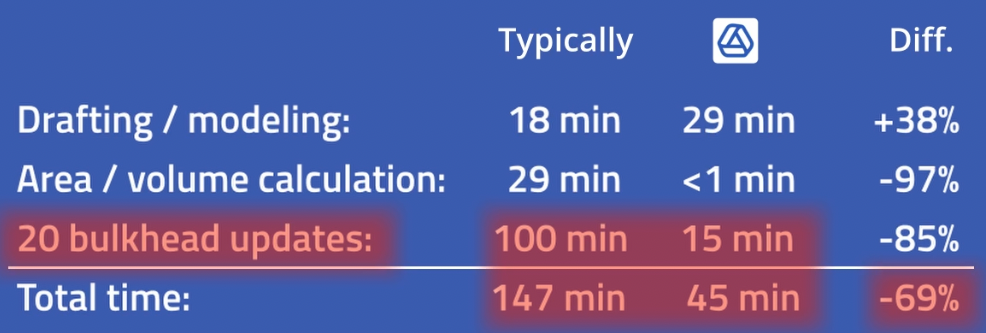

However, if we assume more realistic workflow, the difference grows to almost 70%!

That’s 70% less time spent on design!

Summary

Naval Architect combines made-to-measure drafting functions with the 4th dimension of the geometry – the database. Thanks to that, it allows the ship design offices to save even 70% of time, especially in early stages of project development. And these are not just empty numbers! We’ve actually shown how Naval Architect improves the efficiency of the ship design workflow in our last video, where we compare it to common CAD and the spreadsheet.

Try us!

Try our Sandbox Version and all its features for free: Register now

Our team has worked hard to create the most innovative cloud design software for shipbuilding. With this new technology, we aim to actively push the shipbuilding industry to the era of connected design and Digital 4.0.

In case of any questions or feedback, please shoot us a message and we will get back to you asap.

We are looking forward to see you on the Sandbox!