Heating, Ventilation, and Air Conditioning (HVAC) are one of the most complex and widespread, yet…

Why a 3D CAD model is not a Digital Twin

Digital Twin is the new buzzword of the industry. Let’s take a closer look at what it means exactly to understand what benefits we can expect from it.

Terminology made precise

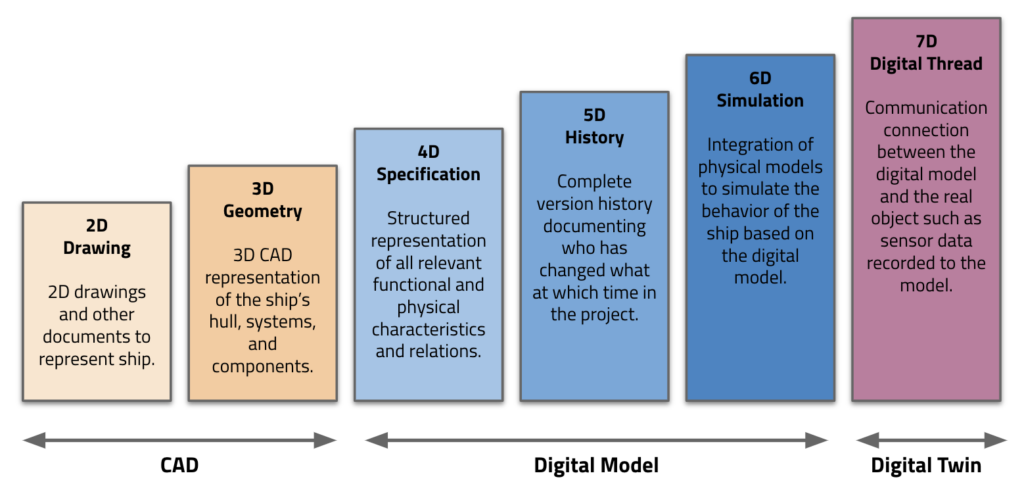

A digital twin belongs to the space of digital representations to describe technical products. An example of particular interest to us is the digital representation of vessels. We differentiate three main categories of digital representations:

- Geometry Models: describe the geometry of a product. 2D CAD drawings are the simplest form, but nowadays 3D CAD models are widely used. Yet a 3D CAD model is really just a particularly precise form of a drawing that leaves less room for interpretation.

- Digital Models: describe the full range of technical data connected with a product. This includes functional requirements and specifications and may even incorporate the simulation of the product’s physical behavior. A product model usually includes the geometry, but this is really only one single piece of the puzzle.

- Digital Twins: are digital models which live in a feedback loop with reality. The two main differences to the aforementioned categories are therefore the existence of a real object and the communication between the real object and the digital model.

The evolution from a geometry model (CAD model) to Digital Twins can be seen in the following illustration.

What is a digital twin good for?

Unless your CAD model does not have a communication channel with a vessel sailing the seven seas, it can’t be a digital twin. It would avoid quite some headaches down the road to keep the CAD data for potential retrofits. This is, however, not exactly the same as a feedback loop with the actual vessel. This is more of keeping a solid documentation over the vessel’s lifetime.

Unless your CAD model does not have a communication channel with a vessel sailing the seven seas, it can’t be a digital twin.

Digital twins are nevertheless actively discussed because there are many use cases. Just think about maintenance: we could efficiently track the maintenance record of a vessel. Alternatively, we could leverage sensor data to predict maintenance needs before something breaks. This, however, requires a model which is less focused on geometry, but strives for a functional description of the systems up to ability to simulate physical behavior. In short: a product model rather than a geometry model.

So how does Naval Architect fit in here?

If we take a look at the Evolution from CAD over Digital Model to Digital Twin, the current version of the Naval Architect platform can be seen as a 5D Digital Model. It includes the geometric model of the ship (3D), the specification (4D) including all relevant functional and physical characteristics and relations as well the history (5D) with the complete version history documenting who has changed what at which time in the project. A 5D Digital Ship model at the current status already is a game changer for the shipbuilding industry as it offers a vast majority of the benefits a Digital Twin can. Most importantly, Naval Architect helps to maximize the business efficiency and reliability to make sure that even the most complex projects are consistently delivered on time and budget.

Let’s draw a conclusion

The feedback loop with reality is the unique characteristics of a digital twin. This does not apply for CAD models, so they are not a digital twin. Moreover, analyzing the use cases of digital twins in practice reveals that CAD is usually not even the kind of data which is communicated between the vessel in service and the digital model.

Are you ready to leverage the benefits of digital twins your projects?

Let us discuss your challenges in a 30-minute call. Together we will identify opportunities and find out how your processes can be made more efficient and reliable by using our technology.

➡︎ Schedule a discovery call here

Learn more about the 5D DIgital Ship model

Our Platform manages technical project data based on a 5D Digital Ship Model that project teams collaborate on in the cloud. If you want to learn more about how Naval Architect enables maximum efficiency and reliability in ship design, feel free to visit the following links: